Our Know-how

Since the creation of Cidres Le Brun in 1955, our ciders have won numerous awards in national and international competitions.

All our ciders are 100% pure juice, with natural effervescence and unpasteurized.

Our Know-how

Since the creation of Cidres Le Brun in 1955, our ciders have won numerous awards in national and international competitions.

All our ciders are 100% pure juice, with natural effervescence and unpasteurized.

Our medals

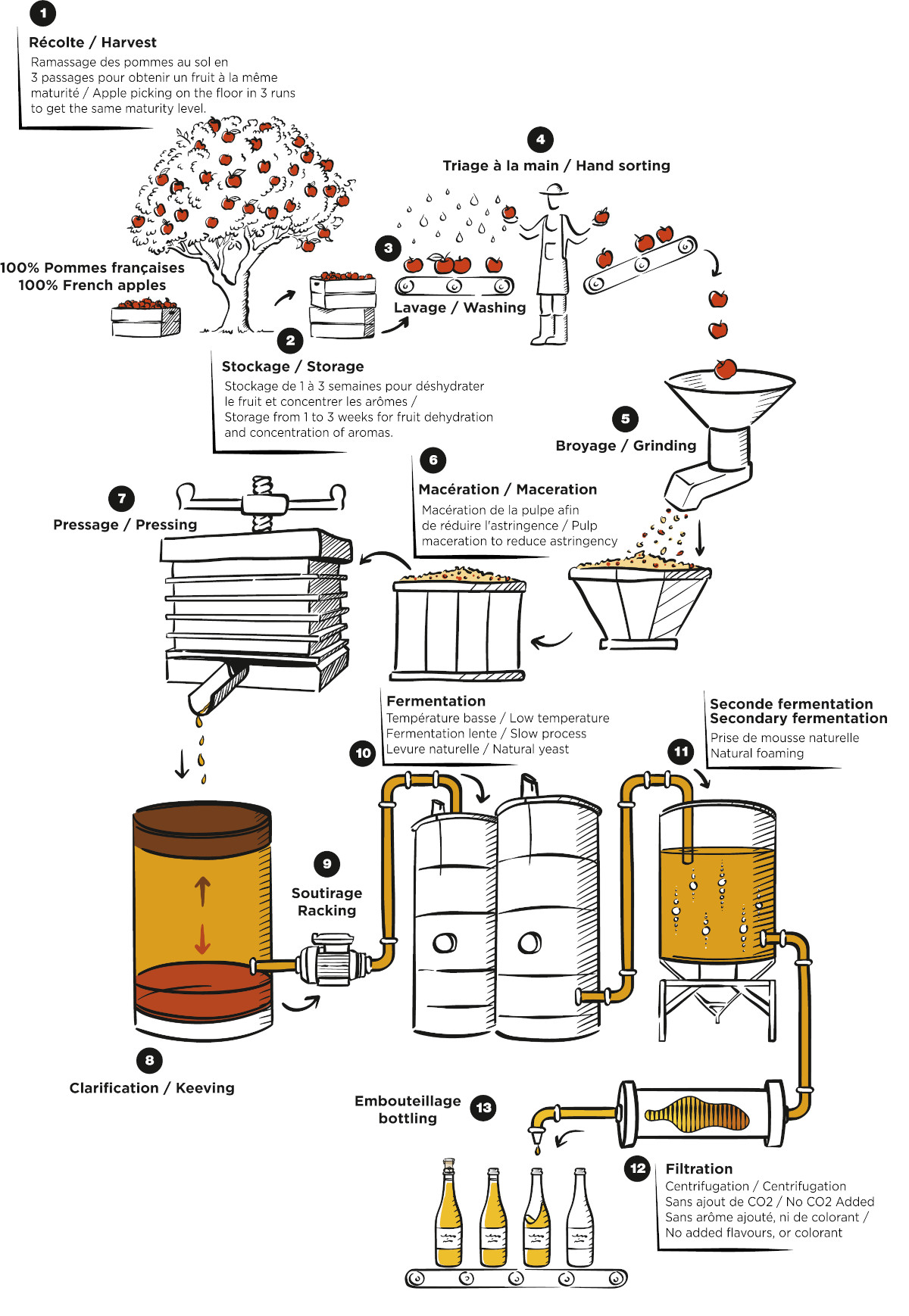

OUR 13 STEPS IN MAKING A PREMIUM CRAFT CIDER

Want to know more?

Follow us in the process of making 100% Breton artisanal cider.

1. Harvest

It all starts in the orchards. About 20 different varieties of bitter and bitter-sweet cider apples are used to make our ciders and apple juices. To name a few: Kermerien, Marie Ménard, Douce Moên, Peau de Chien, Douce Coêtligné. They are collected on the ground in order to guarantee maximum maturity. As they do not all fall at the same time, we make about 3 runs per orchard.

2. Storage

The fruits are stored in 500kg crates and transported to Plovan for processing.

3. Washing

The fruits are washed with water.

4. Sorting

The apples are sorted by hand in order to eliminate “rotten” apples and thus guarantee the quality of our juices.

5. Grinding

Once sorted, our fruits are crushed to obtain small apple cubes ideal for juice extraction.

6. Maceration

The pulp obtained will be left for a few hours in a opened tank in order to oxygenate the product and break the astringency of our apples.

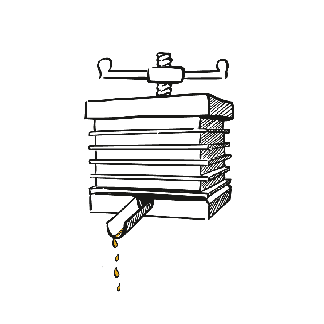

7. Pressing

Finally, the pulp is pressed to obtain pure apple juice.

8. Keeving (Clarification)

The pure apple juice obtained is clarified using the keeving method. This allows part of the pectins to be trapped in the form of a brown cap. This traditional Breton method is highly envied by other countries, but not all varieties of apples allow this clarification method to be achieved.

9. Racking

Once the clarification is done, the pure juice is isolated from the brown cap by racking.

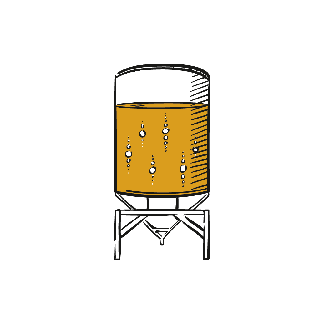

10. Fermentation

Our juices are then stored in temperature-controlled tanks. The cold puts the natural yeasts from the fruit to sleep, and the juices therefore remain pure apple juice without alcohol until we decide to ferment them. We then need between 4 and 6 months of fermentation at low temperature to obtain our ciders. These slow fermentations allow the aromas to develop finely.

The indigenous yeasts then convert the natural sugars from the apple into alcohol. The longer you wait, the less sugar and the more alcohol you get. We thus go from a pure apple juice to a sweet cider, then semi-dry and finally dry.

11. Second fermentation

At the end of fermentation, we transfer our ciders to isobaric vats which will allow the natural foaming to take place by forcing the CO2 produced during fermentation to dissolve in the cider. This process makes it possible to obtain a fine bubble as opposed to artificial carbonation which gives large bubbles more aggressive in the mouth.

A large majority of industrial cider makers but also of certain artisan or farm producers make ciders with artificial CO2. This is not the case at Cidre Le Brun Bigoud where we want to respect the product until the end.

12. Filtration

The ciders are then filtered to remove deposits and yeasts. This filtration makes it possible to stabilize the products over time. No pasteurization for our ciders because this distorts the fruit aromas and gives the cider aromas of cooked apples.

No flavorings are added to our products.

13. Bottling

The ciders are finally ready to be bottled.

From apple to bottle about 6 months were needed.

Several formats are available.

- Champagne-type bottle 75cl or 37.5cl with its cork stopper and its muselet for our cider ciders and sparkling apple juice.

- 33cl type “long neck” with capsule.

- 100cl glass jar for our flat apple juice.

It only remains to enjoy in moderation.

Somes dates

1955

Creation of Cidre Le Brun by Jean Le Brun

1991

Takeover of the company by Dominique Le Brun at the age of 22

1995

Integration of the “produced in Brittany” network

1996

Creation of Cidres Bigoud (formerly “Les Celliers de la Ville d´Ys”)

2008

Investment in new stainless steel tanks (essential tool for the quality of our ciders)

2015

Renovation of our juice production room

2016

Obtaining the PME + label / CSR approach

2018

Obtaining our IFS Certification (International Food Standard)

2021

Installation of a new chiller with heat recovery in order to optimize our energy balance

2022

Renovation of the bottling line